AB Flygindustri

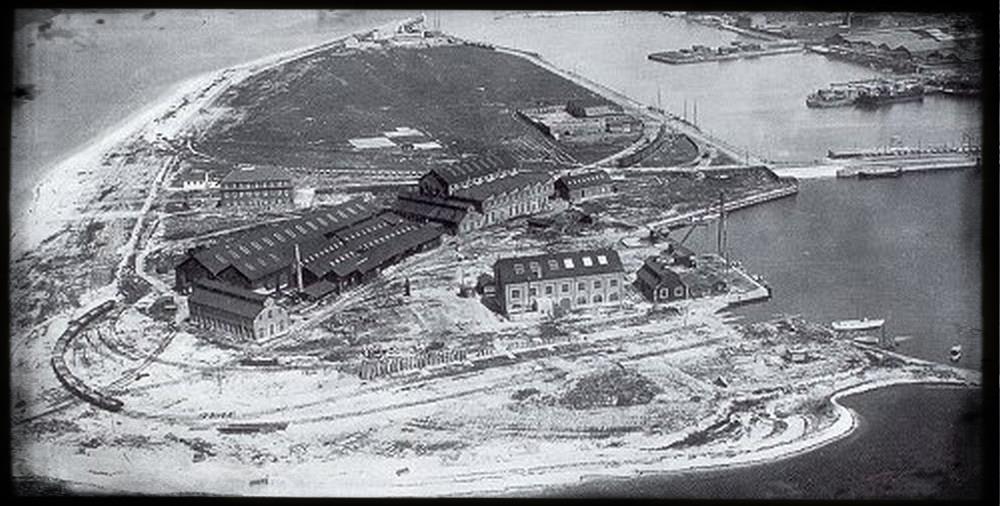

The Limhamn Production Plant during Mid-Twenties

A major problem of the post WW I aviation industry in Germany were the massive restrictions on German aircraft designs. The Allies limited the engine power and any military equipment or use of German aircraft. Initially Hugo Junkers tried to overcome this problem with the Joint Venture with the Soviets at Fili in Moscow. While Junkers at Dessau produced parts, which apply to the Allied restrictions, further military equipment was added from the Fili production in Moscow. In 1924 larger Junkers aircraft, i.e. the Junkers G24 became available, which needed more powerfull engines, than were allowed by the restrictions. That meant, that a less powerful aircraft with identical fuselage, the Junkers G23 was built at Dessau and flown out of Germany to an international partner, who performed the engine change with more powerful engines for customers outside of Germany. Due to the increasing difficulties with the Soviets in Fili, it became necessary to find another international partner for this purpose.

In 1924 Junkers started discussions with Emanuel Nobel about the foundation of a Swedish aircraft company, but these discussions came to no result. At the same time the two brother Carl and Adrian Florman contacted Junkers and asked for his support in building Sweden’s first commercial airline. Already in March 1924 these discussions led to the foundation of Aero Transport AB, which started operations between Stockholm and Helsingfors with Junkers aircraft within the Junkers Luftverkehrs AG network.

Further discussions between Florman and Junkers about the foundation of an aircraft production facility were joint by the English Blackburn company, which left the discussion before any results were reached. On January 16th 1925 the AB Flygindustri – Afi was founded by Adrian Florman, John Bjoerk, Alvar Elmstroem, Gustaf von Hofstein, Carl Bonde and Friedrich Treischke for Junkers with a shareholding capital of 150.000 Skr. A total of 82% of the share capital was owned by Junkers, however due to the fact, that a maximum of 50% of the share capital might belong to foreign shareholders in Sweden, 32% were holded by Swedish dummy shareholders on behalf of Junkers. Friedrich Treitschke was appointed as the first director of A.B. Flygindustri. Treitschke was a Junkers engineer and Swedish national. Since 1926 Treitschke and Adrian Florman changed this position for several times. In 1930 another Junkers engineer Hermann Mierzinski took over the position from Treitschke. Two operational units were established, the maintenance organisation was headed by Vogler, while the aircraft production unit was managed by Kuerner.

An acceptable production site for AB Flygindustri was found at a former shipyard at Limhamn near Malmo in the South of Sweden. This site was located on a small island, which was reachable by a bridge. Between 1916 and 1921 this areal was used by a Swedish shop manufacturer and about 10 ships with minimum 2000 tons were built here during five years. After WWI the demand for new ships decreased and the areal was dropped off. It was an optimal site for A.B. Flygindustri, when they came here in 1925.

In February 1925 the first workers appeared at Limhamn. Some Swedish, but most people came from Junkers Dessau for training purposes. Officially AFI was a repair shop for A.B. Aerotransport aircraft, but quickly it became a completion center for new Junkers aircraft. Parts for these aircraft were sent from Dessau to Limhamn, where the aircraft was built. The Limhamn aircraft had not to apply with the Allied restrictions in Germany. Therefore, aircraft built at Limhamn were more powerfull than the original ones in Germany.

To gain experience, two Junkers A20Ws were sent to Limhamn for repair works together with 10 floaters. In March 1925 A.B. Flygindustri started with the completion of the first Junkers G24 for A.B. Aerotransport at Limhamn. Parts for these aircraft arrived from Dessau. These three aircaft were completed in May 1925 and delivered to Aerotransport. As the G24 was also intended as a military aircraft for Russia, Limhamn started to produce the military equipment parts of the K30, which was the militarized G24. Export Licenses were aquired for the R24 and R02. The Limhamn staff quickly grew and in November 1925 there were 475 people working at A.B. Flygindustri.

G23/G24 Conversion Programme at Limhamn 1925/26

The initial workload of the new Limhamn facilities came from the G23/G24 conversion programme. The original Dessau built G23 was underpowered due to the requests of the Allied Control Commission in Germany. Several engine alternatives had been designed at Dessau but were not allowed in Germany. Therefore the Dessau built G23 were flown to Flygindustri at Limhamn and were reengined there with more powerful engines. About 11 G23s were flown to Sweden in 1925 and got Swedish registrations there. Now they were converted to the stronger G24 standard. Some remained in Sweden with AB Aero Transport but most returned to Germany after that conversion.

The first original built G24 was c/n 846, which was completely built at Limhamn in 1925. A further two G24 (c/n 847 and 851) of the first batch followed during the same year. The second batch of the G24 (c/n 902 to 911 and 917 to 926) was also completely built at Limhamn between 1925-26. In 1926 the Allied restrictions in Germany came to an end. By now, Junkers could built the stronger G24 versions directly at Dessau. Only two further G24 (c/n 931 and 932) of the third (1926) batch were built at Limhamn.

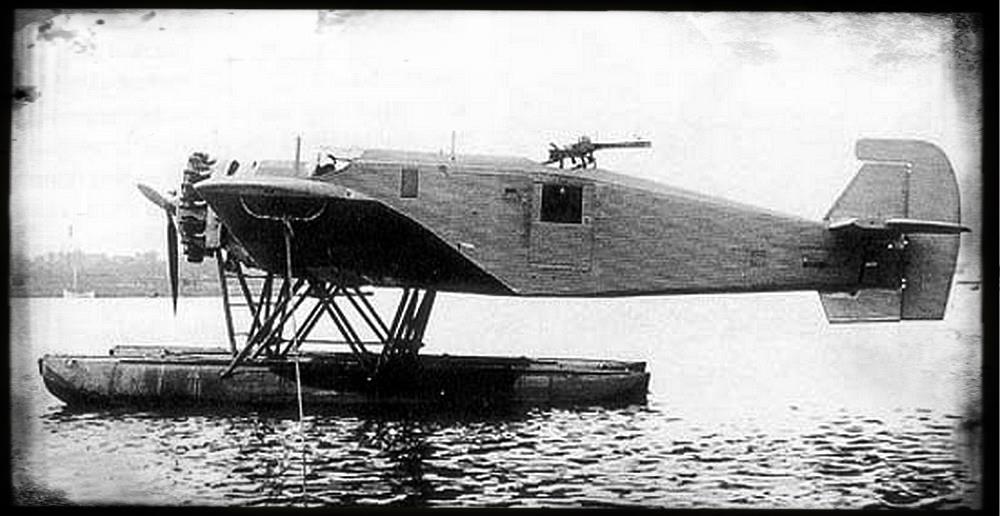

K30 Military Adaption Programme at Limhamn (from G24/R42)

AB Flygindustri K30

By 1926 Junkers was allowed to built aircraft without any performance restrictions in Germany. But the Allied Commissions still refused any military equipment onboard these aircraft. A single military derivate of the G24 was built at Dessau as the Junkers K30 K30 The R42 got two machine gun towers on the roof of the aircraft and a third tower below the aircraft. The bombs were placed under the fuselage, but also some bombs were placed under the wing. The serial production of this military aircraft should be performed at Flygindustri at Limhamn. By 1926 the complete G24 production was transfered back to Dessau. The aircraft built there were civil G24 aircraft. They were flown to Limhamn and were equipped there with military equipment to the K30 standard. The Limhamn type designator for this military variante was R42 (reversed numbers of the G24!) The new type designator at Limhamn was created to prevent Junkers from attacks from the Allied Commission. Most of the R42 were delivered to the USSR and were used there as bomber aircraft. Some of those Limhamn R42s were again converted at the Fili facility and named Ju G-1. The first 15 aircraft were flown to Russia by the end of 1926. A further 8 followed in 1927 Further six R42s were sold to Chile since autumn 1926 and a single R42 was delivered to Spain.

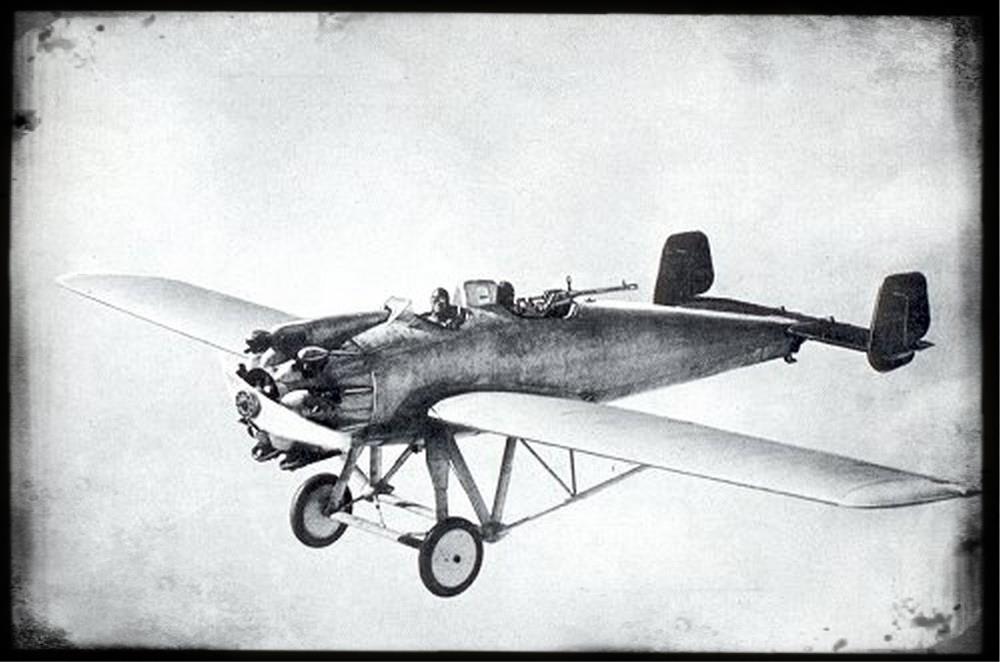

R02 (converted from A20)

Already in 1925 Limhamn started with military conversions of Junkers civil aircraft. The first aircraft to be equipped with military components was the Junkers A20. A Junkers A20 (c/n 456, built in 1923) was flown to Limhamn in 1925 and reregistered as S-AAAJ. The observer seat was equipped with a turnable machine gun tower. Like the G24/R42 also a new type designator was used for this military A20 as R02 (reversed numbers again!) But only a single R02 was built at Limhamn. Russian orders were managed by Fili as Ju 20. A large number of military A20s were finally built in Turkey as light bomber aircraft during 1925/26. They were built under license with parts produced by the Dessau facilities. About 65 of these Turkish R02/A20s were built. Finally Limhamn was unable to get other orders for that aircraft.

R41 (converted from A25, K45)

During 1926 the sole R02 at Limhamn was equipped with a Junkers L2 engine to A25 standard. Also this A25 was redesigned at Dessau to military standard and designated K45. The Limhamn version became the R41. This derivate was sold in several numbers from Limhamn.

K39 (converted from A32)

Limhamn K39 Advertisment

In 1927 a single A32 three seated aircraft was modified at Limhamn. The military variante K39 had one fixed machine gun at the pilot position and a turnable tower at the rear seat. A third machine gun was available at the observer's center seat for lower defense. Only 100kg bomb payload could be ferried. No customers are known for that type. Only a single K39 was converted at Limhamn.

R53 (converted from A35, K53)

AB Flygindustri K53

Finally the A35 was modified to military standard by Junkers as the K53. Again the observer seat was equipped with a turnable machine gun tower and the aircraft was designated R53. During 1926 several A20s were flown from Dessau to Limhamn and reengined and modified to R53 standard there. Later, A35s were directly produced at Dessau and send to Limhamn for final military equipment About 15 R53 were built at Limhamn.

K37 (converted from S36)

A single military K37 was modified at Limhamn from the civil S36 standard. This prototype was bought by Mitsubishi in Japan and built under license for the Japanese Airforce as a bomber aircraft in 1931 under the designator Ki-1/2.

K43 (converted from W34)

AB Flygindustri K43

In 1926/27 Junkers modified the W34 to military K43 standards. About 16 military K43 were built at Limhamn of which 6 were sold to Finland, 5 to Portugal 5 to Argentina and Bolivia.

K47 (converted from A48)

AB Flyindustri K47

The K47 was a two seated fighter aircraft modified from the A48 standard. The observer's seat was turned to tail and equipped with a turnable machine gun. Several K47 were built for China, as well as two aircraft for Russia in 1930.

K54 (converted from Ju52)

AB Flygindustri K54

A single Ju52 was converted to military K54 standard at Limhamn in 1932. This Ju52 was the single engined Ju52ce (c/n 4004), which was equipped with floaters. In December 1932 this aircraft was flown to Limhamn and got a torpedo system. The aircraft returned to Germany with Swedish registration and was tested at Travemunde. No further Ju52 modifications are known at Limhamn.

The following table contains the different aircraft types built at Limhamn as well as the assumed production numbers of Limhamn between 1925 and 1935

AFI - Limhamn Production Figures

|

| 1925 | 1926 | 1927 | 1928 | 1929 | 1930 | 1931 | 1932 | 1933 | 1934 | 1935 | Total |

| Junkers R02 (A20) |

| 1 |

|

|

|

|

|

|

|

|

| 1 |

| Junkers R53 / K53 |

| 1+1*) | 6 | 5 | 11+1*) | 2 | 1 | 2 | 2 |

|

| 32 |

| Junkers G24 | 6 | 5 | 1*) |

|

|

| 5+1*) |

|

| 1*) |

| 19 |

| Junkers R42 / K30 | 3 | 19 | 2 | 9 |

|

| 2 |

|

|

| 2 | 37 |

| Junkers W33 / W34 |

|

|

|

|

| 1+1*) |

|

| 1 | 10 W34 | 10 W34 | 23 |

| Junkers K43 |

|

|

|

|

| 1 | 6 | 13 |

|

|

| 20 |

| Junkers K37 (S36) |

|

| 1*) | 1 |

| 1 |

|

|

| 1*) |

| 4 |

| Junkers K39 (A32) |

|

| 1 |

|

|

|

|

|

|

|

| 1 |

| Junkers A50 |

|

|

|

|

| 2 |

| 1 |

|

|

| 3 |

| Junkers F13 |

|

|

| 1 |

|

|

|

|

|

|

| 1 |

| Junkers Ju52 / K54 |

|

|

|

|

|

|

| 0+2*) |

|

|

| 2 |

| Total | 9 | 27 | 11 | 16 | 16 | 12 | 22 | 20 | 4 | 14 | 12 | 153 |

*)Modifications or completion of Dessau built aircraft

In 1934 AFI discussed a possible torpedo bomber design with the Swedish Air Force. They proposed the Junkers K85 and the Swedish Air Force was highly interested in that design. However, the Swedish Government favorized the British HP83 Hampden bomber and ordered these instead of the German K85.

The Junkers engagement in the AB Flygindustri slowed down, when the Nazis got control about the Junkers consortium since 1934. When the Swedish laws changed on 1st July 1935 and asked the Swedish companies to account for their foreign shareholders, AFI was finally liquidated on request of the German shareholders. On July 15th 1935 the company was officially closed. The Limhamn facility was taken over in the same year by A.B. Plantindustri, which operated the site until the mid fifties. The last aircraft left Limhamn in August 1935. It was a W34 (c/n 2835) delivered to the Swedish Air Force. The last 90 employees left Limhamn in September 1935. Three unsold K30 airframes were scrapped at Limhamn before closing the facility.

In total the AB Flygindustri was not really a German/Swedish joint venture like Fili. Furthermore was the Limhamn facility more or less a complete Junkers production facility with an own marketing name, which prevented Junkers from trouble with the Allied Commissions. Limhamn was the Junkers Military Aircraft facility during a period, when it was not allowed to built military aircraft in Germany. Consequently the Limhamn engagement went down, when the Nazis again allowed the military aircraft production in Germany.

Further Reading at other Sites:

Limhamns Företagsgroup (in Swedish)

Sten Gronberg's Site (in Swedish)

Literature:

- Lennart Andersson

AB Flygindustri i Limhamn

Flyghistorisk Revy, 1998, ISBN No. 0345-3413, 158 pages

introduced Mar 2004, transfered Dec 2017

http://hugojunkers.bplaced.net/

contents last updated 14 Mar 2004